Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-07-05 Origin: Site

When you use a polishing machine on stainless steel, you want the best buffing compounds for a smooth and shiny finish. Some top choices are Greystar, Brown Tripoli, Green Rouge, Polina, Black Emery, Dialux Grey, and Stainless Buffing Compound. These compounds help take away scratches and make metal shine. Each compound works with the metal to make the surface better and give you the finish you want. Polishing stainless steel is easier because these buffing compounds lower the force needed and help clean faster. You can trust these compounds to make any metal project look perfect.

Begin polishing stainless steel with coarse compounds like Black Emery. These help take away deep scratches. Next, use medium compounds such as Greystar or Brown Tripoli. These make the surface smoother.

Finish polishing with fine compounds like Green Rouge or Polina. This gives your stainless steel a bright, mirror-like shine.

Pick buffing wheels that fit your compound type. Use sisal or treated cotton for cutting compounds. Use soft cotton or flannel for finishing compounds.

Always clean the metal between each polishing step. This stops scratches and helps you get a clear, shiny finish.

Wear safety gear like gloves and glasses when you polish. Keep your workspace clean and machines steady. This keeps you safe and helps you get good results.

When you polish stainless steel, you should choose the right buffing compounds for your job. Each compound works best at a certain step. Some are good for taking away scratches. Others help make the metal smooth and shiny. The table below shows how each compound is different by grit, finish, and use.

| Compound | Grit Level | Finish Level | Best Use Case | Buffing Wheel Type |

|---|---|---|---|---|

| Greystar | Medium | Satin to Semi-Gloss | Cutting, removing firescale | Sisal, treated cotton |

| Brown Tripoli | Medium | Satin | Cleaning, scratch removal, refining | Sisal, spiral sewn |

| Green Rouge | Fine | Mirror | Final polish, high-gloss finish | Loose cotton, flannel |

| Polina | Fine | Sparkling | Jewelry, watches, white gold, finish | Soft cotton, flannel |

| Black Emery | Coarse | Matte | Heavy cutting, deep scratch removal | Sisal, treated cotton |

| Dialux Grey | Fine | Bright | Final buffing, light scratch removal | Soft cotton, flannel |

| Stainless Buffing Compound | Medium-Fine | Bright to Mirror | All-purpose stainless finish | Cotton, flannel |

Tip: Start with coarse compounds like Black Emery to get rid of deep marks. Then use medium compounds like Greystar or Brown Tripoli to make the metal smoother. Finish with Green Rouge or Polina to make it shine like a mirror.

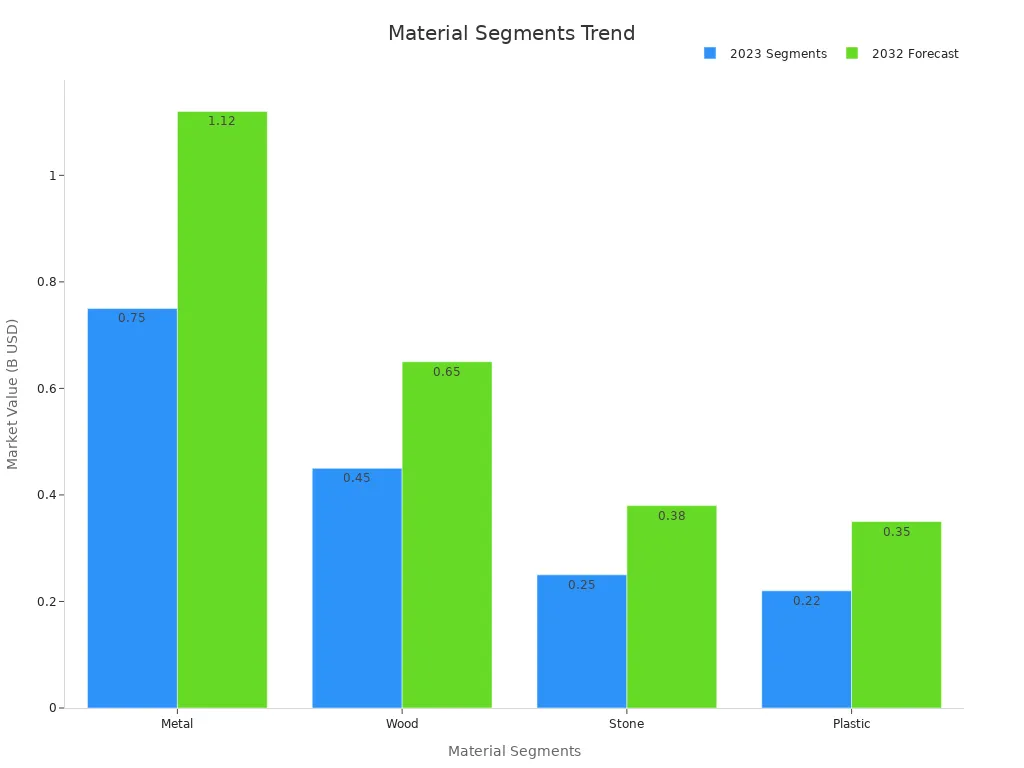

You can see how each buffing compound changes the metal by looking at the chart below. It shows how different steps in polishing change how smooth and shiny the metal looks. Using the right buffing wheels and compounds helps you get the best finish.

Tests show that both the compound and the buffing process really change the surface of stainless steel. You get the best results when you use the right compound with the right buffing wheel. For example, use Greystar or Brown Tripoli for cutting and smoothing. Use Green Rouge, Polina, or Dialux Grey for the last step. This way, you can always make the metal look perfect.

Greystar is a medium-grade compound for stainless steel. It helps take off firescale and smooths rough spots. You use it with fixed buffing wheels like sisal or treated cotton. Greystar starts the polishing by cutting away flaws. It gets the metal ready for a finer finish. The surface will look soft and shiny after using it. This makes it ready for the next step. Many people pick Greystar because it works well and gives a satin or semi-gloss look.

Key Features:

Medium grit for effective cutting

Prepares stainless steel for further polishing

Works best with sisal or treated cotton buffing wheels

Best Use:

Use Greystar to remove marks and get the metal ready for a shiny finish.

Brown Tripoli is a popular compound for cleaning stainless steel. It removes scratches and makes the metal smooth. Brown Tripoli works with sisal or spiral sewn buffing wheels. It helps polish away flaws and leaves the metal even and clean. This compound is safe for stainless steel. People also use it on wood and other metals.

Key Features:

Medium grit for scratch removal

Cleans and refines the metal surface

Pairs well with spiral sewn buffing wheels

Best Use:

Pick Brown Tripoli when you need to clean and smooth stainless steel before making it shiny.

Green Rouge is used to make stainless steel very shiny. It is for the last step of polishing. Green Rouge has fine abrasives and works with loose cotton or flannel wheels. This compound helps polish the metal until it shines like a mirror. Many jewelers and metalworkers trust Green Rouge for a bright, flawless look.

Key Features:

Fine grit for final polishing

Delivers a mirror-like, high luster finish

Best with loose cotton or flannel buffing wheels

Best Use:

Use Green Rouge when you want stainless steel to look very shiny and bright.

Polina is a fine, orange compound for a sparkling finish. It is good for jewelry, watches, and white gold. Polina works best with soft cotton or flannel wheels. This compound helps polish small items and gives them a high shine. Many people who make jewelry or watches like Polina for its bright, sparkling look.

Key Features:

Fine grit for delicate polishing

Creates a sparkling, high shine

Ideal for jewelry and small metal items

Best Use:

Pick Polina when you want a sparkling finish on stainless steel jewelry or watches.

Black Emery is a coarse compound for heavy cutting. It removes deep scratches and tough marks from stainless steel. Black Emery works with sisal or treated cotton wheels. This compound starts the polishing by smoothing rough areas. It gets the metal ready for finer compounds. It leaves a matte finish that you can polish more later.

Key Features:

Coarse grit for heavy cutting

Removes deep scratches and marks

Best with sisal or treated cotton buffing wheels

Best Use:

Use Black Emery to take off heavy flaws before using finer compounds.

Dialux Grey is a fine compound for a bright finish. It is used for final buffing and light scratch removal. Dialux Grey works best with soft cotton or flannel wheels. This compound helps polish the metal to a high shine. It is great for the last step in polishing. Many people like how Dialux Grey makes the metal look bright and shiny.

Key Features:

Fine grit for final buffing

Brightens and polishes the metal

Works with soft cotton or flannel buffing wheels

Best Use:

Pick Dialux Grey for the last buffing step to get a bright, shiny finish.

Stainless Buffing Compound is good for many polishing jobs. You can use it for cutting or finishing, depending on the wheel. This compound works with cotton or flannel buffing wheels. It helps you get a bright or mirror finish on many stainless steel items. Many people like brands like Eastwood for their support and satisfaction guarantee.

Key Features:

Medium-fine grit for versatile use

Suitable for both cutting and finishing

Works with cotton or flannel buffing wheels

Best Use:

Use Stainless Buffing Compound when you want one compound for both polishing and finishing stainless steel.

For the best results, you can trust Custom Manufacturing and Polishing, Inc. Their team uses the right buffing compounds and skills. They make stainless steel very shiny and bright on every project.

You need to pick the right polishing compound for your finish. If you want to get rid of deep scratches, start with a Tripolis compound. This compound helps take away marks and makes the metal smoother. Use an intermediate compound if you want a satin or semi-gloss look. For a mirror polish or high shine, use a finishing rouge. This last step makes the metal very shiny and bright.

Think about your goal:

Deburring: Use a cutting compound to take off rough spots and scratches.

Polishing: Use an intermediate compound to smooth the metal and make it shinier.

Burnishing: Use a finishing rouge for a mirror or high shine.

The size of the abrasive media is important too. Small media give a smoother finish but take more time. Big media remove scratches faster but may not make the metal as smooth.

Your polishing machine helps decide which compound is best. Fixed buffing wheels like sisal or cotton work well with bar compounds. Vibratory or tumbling machines usually use paste or liquid compounds. Some machines need compounds that clean or stop rust. Always use the right compound form for your machine to get the best shine.

Tip: Wet tumbling compounds work well with vibratory machines. They help clean, polish, and protect your stainless steel.

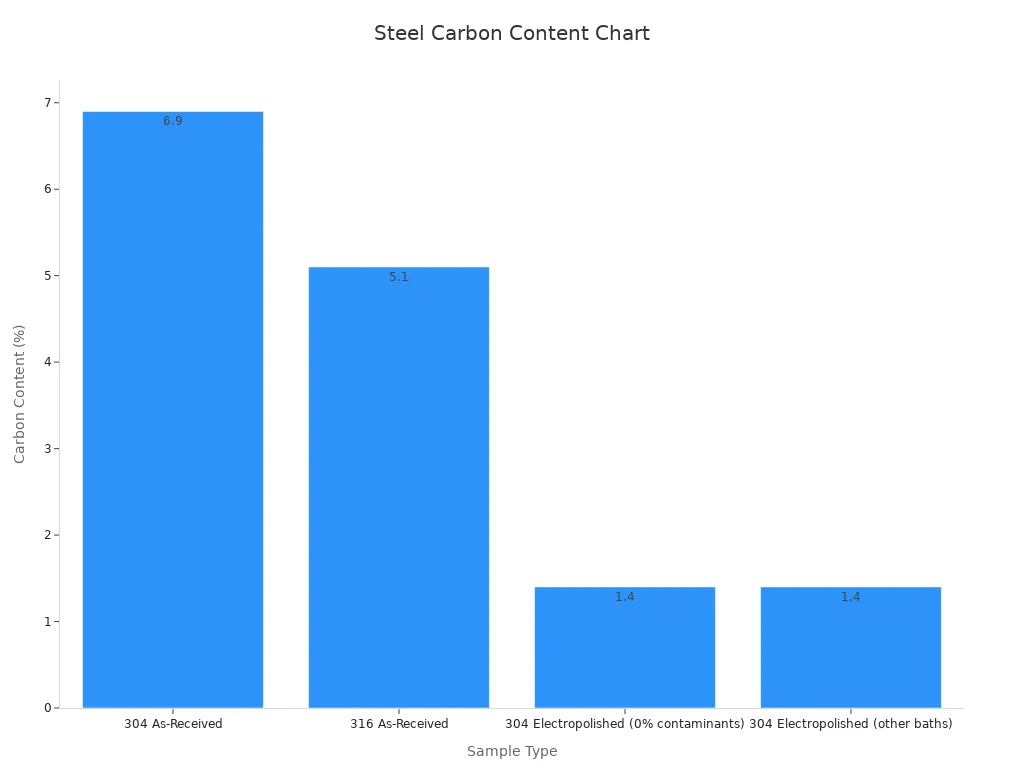

Different stainless steel grades polish in different ways. Grades like 304 and 316 have special features. For example, 316 has more chromium and molybdenum. This helps it fight rust and gives a better shine after polishing. The table below shows how the metal changes after polishing and how it affects the look:

| Sample Type | Carbon Content (%) | Chromium Content (%) | Iron Content (%) | Cr/Fe Ratio |

|---|---|---|---|---|

| 304 As-Received | ~6.9 | Lower | Higher | 0.82–0.86 |

| 316 As-Received | ~5.1 | Lower | Higher | 0.82–0.86 |

| 304 Electropolished (0% contaminants) | ≤1.4 | Higher | Lower | ~1.9 |

| 304 Electropolished (other baths) | ≤1.4 | Higher | Lower | ~1.4 |

You get a better mirror and shine on 316 after polishing because of its chemical mix. Always check your stainless grade before picking a compound.

Polishing compounds come as bars, pastes, and liquids. Bars are best for buffing wheels and taking away scratches. Pastes and liquids work well in vibratory or tumbling machines. Some compounds have extra chemicals to clean or stop rust. Pick the form that fits your machine and the finish you want.

Bar: Good for buffing wheels and taking away scratches.

Paste: Works well for small parts and detailed polishing.

Liquid: Best for big batches in tumbling machines.

Remember: The right compound and form help you take away scratches, polish the metal, and get the shine or mirror finish you want.

You can get a perfect finish on stainless steel by following simple steps with your polishing machine. First, clean the metal to take off any dirt or oil. Use a coarse buffing wheel and a cutting compound to remove deep scratches fast. Move the machine slowly and evenly over the metal. Next, use a medium buffing wheel and compound to get rid of marks left from the first step. For the last polish, use a soft buffing wheel and a fine compound. This step makes the metal shiny and smooth. Wipe the metal between each step so grit does not scratch it. At the end, use a clean cloth to make the metal look bright and like a mirror.

Tip: Pick polishing wheels that go with your compound for the best shine.

Be careful when using a polishing machine. Wear safety glasses and gloves to keep your eyes and hands safe from flying bits. Make sure loose clothes are tucked in and tie back long hair. Place the polishing machine on a flat, steady surface before you start. Keep your hands away from the spinning buffing wheels. Always turn off the machine before you change wheels or compounds.

Many people make mistakes that hurt the final look. Reports say common problems are:

Wrong machine setup causes size mistakes

Bad polishing or buffing makes the surface look bad

Rough handling or cutting causes edge problems

Dirty tools or hands cause contamination

Surface finish problems can cause cracks or weak spots early. Edge problems happen in about 2-5% of cases and can ruin your polish. You can stop these issues by using good polishing steps, keeping tools clean, and checking your work. Studies show that new polishing methods, like magnetic abrasive finishing, help make the surface very smooth and shiny. Trade magazines also say modern polishing can make metal smooth at the nanometer level with few mistakes.

Many people trust Custom Manufacturing and Polishing, Inc. for expert polishing and a long-lasting shine. You can learn about new polishing methods in recent studies and industry news.

You should use Green Rouge or Polina for a mirror finish. These compounds give stainless steel a bright, shiny look. Use a soft buffing wheel for the best results.

You should not use one compound for every step. Start with a coarse compound like Black Emery for scratches. Switch to Greystar or Brown Tripoli for smoothing. Finish with Green Rouge or Polina for shine.

Pick a wheel that matches your compound. Use sisal or treated cotton for cutting compounds. Choose soft cotton or flannel for finishing compounds. This helps you get the best shine.